Process description of pad plating

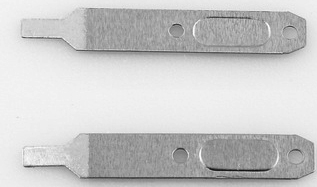

The pin pins of the battery are made of nickel plated stainless steel. Stainless steel itself can't be stained with tin. The purpose of nickel plating is to solder the battery pin on the circuit board with tin. However, as nickel plating is a roll plating process, because the battery pads will overlap during electroplating, sometimes a certain proportion of the battery pads will not be completely electroplated, which will also cause the pads to bend in the electroplating process. The following is a comparison of the two processes.

Nickel plated solder pad (pin pin pin)

A certain proportion of welding pieces cannot be soldered. The welding time is long, and strict time control is required. Improper operation may cause battery damage. A certain proportion of welding pieces are easy to deform and bend in the process of rolling nickel

Local tinplate (pin pin pin)

It can ensure that all welding pieces are 100% easy to be welded, with short welding time and easy to be welded. The welding pieces do not need to be rolled and plated, so there will be no deformation or bending

Fully automatic PVC casing equipment

Laser spot welding and welding feet